| Customization: | Available |

|---|---|

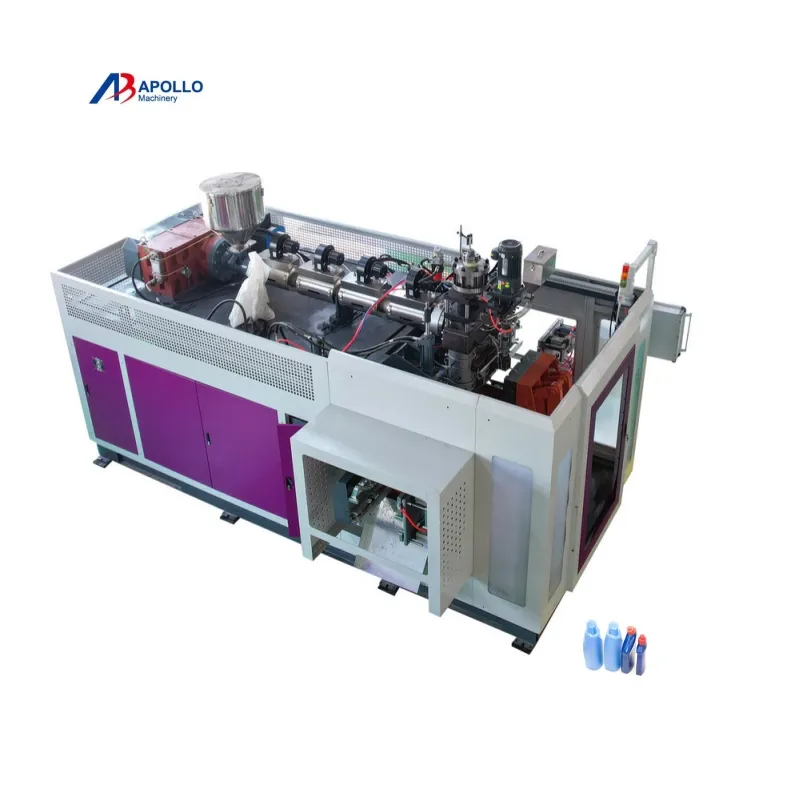

| Type: | Extrusion Blow Molding Machine |

| Raw Material: | HDPE |

| Quantity: | |

|---|---|

Company Profile

Product Description

Product Parameters

| Max. Product volume | 8 L |

| Out put capacity | 750*2 pcs/h |

| Screw diameter | 75MM |

| Screw L/D ratio | 24:1 L/D |

| Screw drive power | 22 KW |

| Screw heating capacity | 7-8 KW |

| No.of heating zone | 4 zones |

| Output of HDPE | 100 KG/H |

| Oil pump drive power | 7.5 KW |

| Clamping force | 80 KN |

| Max.size of mold | 400*430 MM |

| Mold stroke | 170-520 MM |

| Max.die diameter | 170 MM |

| Blowing pressure | 0.6 mpa |

| Air Volume | 0.8 M³/MIN |

| Cooling water pressure | 0.3mpa |

| Water consumption | 80 L/MIN |

| Size of Machine | 4.2x2.2x2.7 m |

| Weight of machine | 7.5 Ton |

| Electronic Parts | |

| Name | Brand |

| Micro computer control system | Japanese MITSUBISHI |

| Tempreture Controller | TAIWAN YANHUA PID |

| Auxiliary Relay | OMRON |

| Contactor | Schneider(France) |

| Electric motor | SImens |

| Power Source | MEANWELL(Taiwan) |

| Transudcer | ABB |

| Hydraulic Parts | |

| Oil pump | HIGH-TECH(Taiwan) |

| Valve | YUKEN(Japan) |

| Oil pump and connection | YUKEN(Japan) |

| Swaled part | HALLITE |

| Air Control System | |

| Cylinder | AIRTAC |

| Air Wave | AIRTAC |

Our Advantages

Detailed Photos

Our service

FAQ

Company Profile

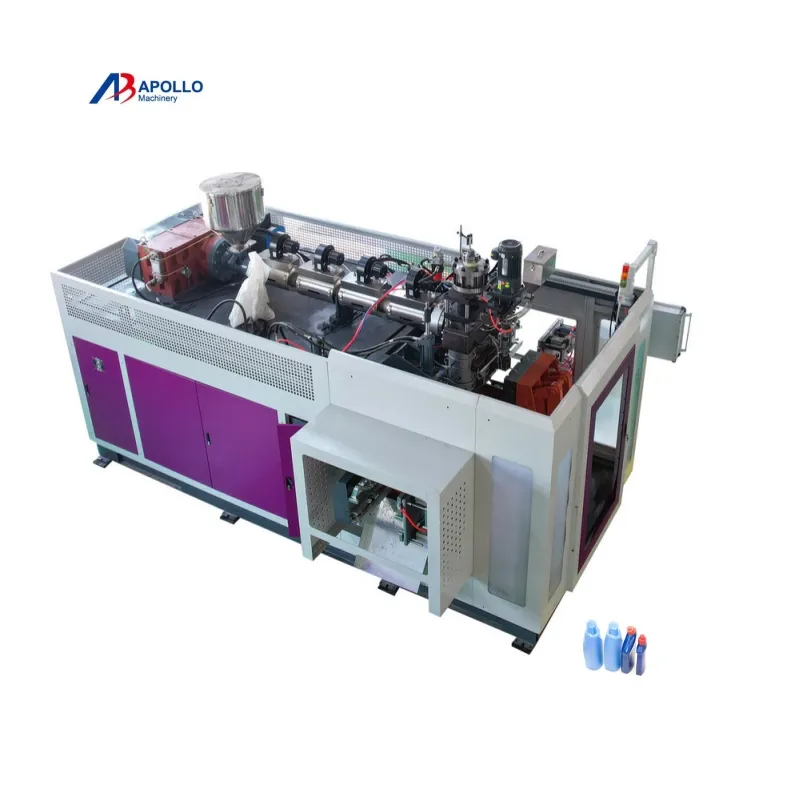

Product Description

Product Parameters

| Max. Product volume | 8 L |

| Out put capacity | 750*2 pcs/h |

| Screw diameter | 75MM |

| Screw L/D ratio | 24:1 L/D |

| Screw drive power | 22 KW |

| Screw heating capacity | 7-8 KW |

| No.of heating zone | 4 zones |

| Output of HDPE | 100 KG/H |

| Oil pump drive power | 7.5 KW |

| Clamping force | 80 KN |

| Max.size of mold | 400*430 MM |

| Mold stroke | 170-520 MM |

| Max.die diameter | 170 MM |

| Blowing pressure | 0.6 mpa |

| Air Volume | 0.8 M³/MIN |

| Cooling water pressure | 0.3mpa |

| Water consumption | 80 L/MIN |

| Size of Machine | 4.2x2.2x2.7 m |

| Weight of machine | 7.5 Ton |

| Electronic Parts | |

| Name | Brand |

| Micro computer control system | Japanese MITSUBISHI |

| Tempreture Controller | TAIWAN YANHUA PID |

| Auxiliary Relay | OMRON |

| Contactor | Schneider(France) |

| Electric motor | SImens |

| Power Source | MEANWELL(Taiwan) |

| Transudcer | ABB |

| Hydraulic Parts | |

| Oil pump | HIGH-TECH(Taiwan) |

| Valve | YUKEN(Japan) |

| Oil pump and connection | YUKEN(Japan) |

| Swaled part | HALLITE |

| Air Control System | |

| Cylinder | AIRTAC |

| Air Wave | AIRTAC |

Our Advantages

Detailed Photos

Our service

FAQ